To produce water waves in the Environmental Fluid Mechanics laboratory, we constructed a piston water wave device |

|

Components: |

|

|

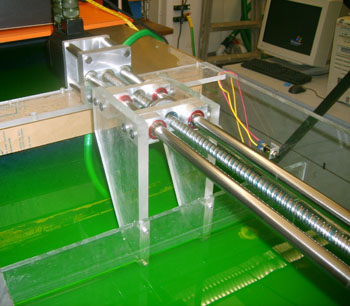

The Wave Generator (left) is comprised of a single 75 cm ball screw which produces 16mm of linear travel per rotation.

The motion for the ball screw is achieved by way of a 1 kW servo motor with a resolution of 2,500 samples per revolution. This resolution allows precise positioning of the paddle.

The servo motor is contolled by use of a user modified LabView program, in conjunction with a 3 -phase servo controller. The user control prgram accepts manual paddle displacement commands, or reads commands from pre-timed ASCII files. |

|

|

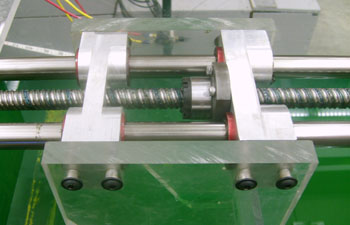

Two 3/4" stainless steel guides ensure the device translates a 24"x10" acrylic paddle along a single axis.

Twin sets of linear bearings slide on the steel guides, with the paddle housing rigidly attached to the guides. |

|

|

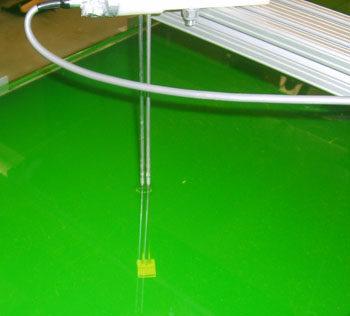

To measure free surface movement, a capacitance based wave gauge was used.

The wave gauge outputs differential dc voltage which can be equated to instantaneous water level with a gain calibration algorithm. |

|

|

The wave gauge is set to a constant height above the base of the flume. At this base position, the voltage signal is set to zero. The gauge is then raised 2cm from the base postion, and gain is adjusted as to achieve a voltage reading of 1v.

Each subsequent variation in free surface elevation causes a voltage change which is directly related. |

|

|

The wave gauges are sampled by a 1000Hz PXI card using a DOS program written by Dr Chin Wu (UW Madison)

Using matlab with an adjustment algorithm, the free surface with respect to time is plotted.

This DAQ device can sample up to 8 simultaneous wave gauge readings. |