Rapidly Installed Breakwater (RIB) Systems

http://chl.wes.army.mil/research/projects/ribs/lotschal.htp

Introduction

Motivations

Objectives

Hard Structures

Soft Structures

Discussion

References

Constructed

by: Michael Dobling

The offloading of military vehicles is cancelled more than 50% of the time

due to incidental wave heights of over 5 feet1. The Department

of Defense requires that offloading of vehicles occur through a sea state 3

condition (5 foot waves), but problems with unloading begin to arise when wave

heights are greater than three feet and wave periods of six seconds. The

Navy often refers to the unloading problems with three foot waves as "the sea

state 3 problem."1 The postponing of these unloading operations can

be very detrimental to the war effort. Dr. Jimmy Fowler states that

"the problem has often been called a 'war stopper' by Army leaders." The U.S.

Army Research and Development Center, Coastal Hydraulics Laboratory in

Vicksburg, Mississippi, has been conducting research on Rapidly Installed

Breakwater (RIB) Systems since 1995. This results of this research have

been

Breakwater structures play a very important role in reducing shoreline and

protecting harbored ships from offshore waves. In our CEE 514 class this

semester, we discussed the different types of breakwaters and their importance The recent development of Rapidly

Installed Breakwater Systems was particularly interesting to me because I am an

active duty member of the United States Navy Civil Engineering Corp and may work

with them in the future.

The

RIBs must accomplish three main goals:

1. reduce incidental wave heights by 50% (SS3 to SS2)

2. have rapid deployment capability

3. require minimal maintenance (withstand SS5)

The research on RIB's first began in 1995, with scale model tests.1

These tests can be seen in the Figure 1. The white v-shaped structure is

the breakwater and there is a model ship contained within the breakwater.

The results of the tests were very positive advancing the scope of the RIBs to

scale model testing in a real environment.

Figure 1. Scale Model Testing. [http://chl.wes.army.mil/research/projects/ribs/physmods.htp]

The next model to be tested was a rigid RIB seen in Figure 2. The

structure was triangular The XM - 99 was

the next RIB to be tested in the ocean. The XM - 99 was tested off the

coast of Cape Canaveral, Florida, from May 20, 1999 to June 04, 1999. The

XM - 99 was constructed in 250ft lengths that were 24ft high and 8ft wide, as

seen in Figure 4. The XM - 99 was said to represent a Venetian blind.

The deployment of the XM - 99 was successful and all performance objectives were

met. The only drawback was that the 250ft sections had to be connected

with a large pin; which was hard to put in place, see figure 5. One of the

lessons learned after testing the XM - 99 was that RIBs made of flexible

materials were much better than rigid RIBs. The XM - 99 was the last

"rigid" structure before the "soft" structures took over.

Figure 4

Figure 5 The first "soft" structured RIB was the Hydro RIB, the

structure of which is shown in figure 6. The Hydro RIB was

tested off the coast of Pensacola, FL in 1997. The Hydro RIB was wound

onto a spool (figure 7), much like wowing thread, and upon reaching the testing

site, unrolled into the ocean. Next, sea water was pumped into the main

chamber making the structure more rigid.

Figure 6

Figure 7 The testing of the Hydro RIB went very well, but there

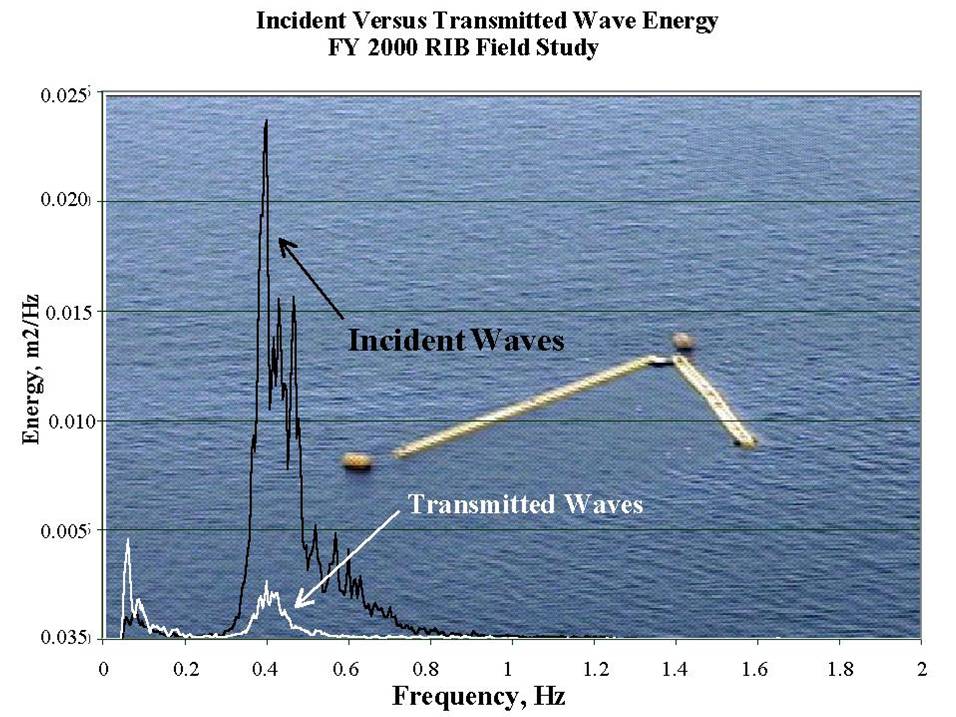

was still room for improvement. The XM 2000 was the next RIB built and

tested off the coast of Pensacola, Florida, for five weeks in the year 2000.

The structure of the XM 2000 was much like the Hydro RIB except more straps,

made of high-strength marine fabrics were added around the hull for increased

strength and the mooring system was changed. The new mooring system, the "Seaflex",

was made of reinforced energy absorbing elastometric cord. This new

mooring system increased the absorption load on the hull and allowed for an

increase in steeper angles mooring , saving space. . The XM

2000 was built in one quarter scale, with the bags six feet in diameter once

they were filled with sea water.1 The tests showed a dramatic

change between the incident wave energy and the transmitted wave energy, figure

8.

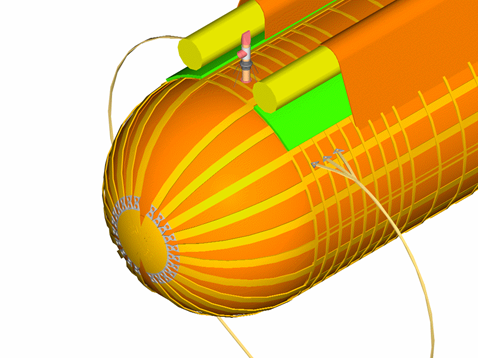

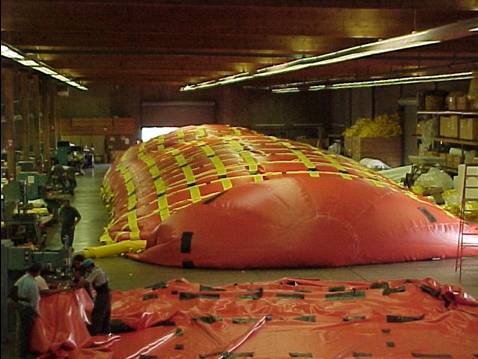

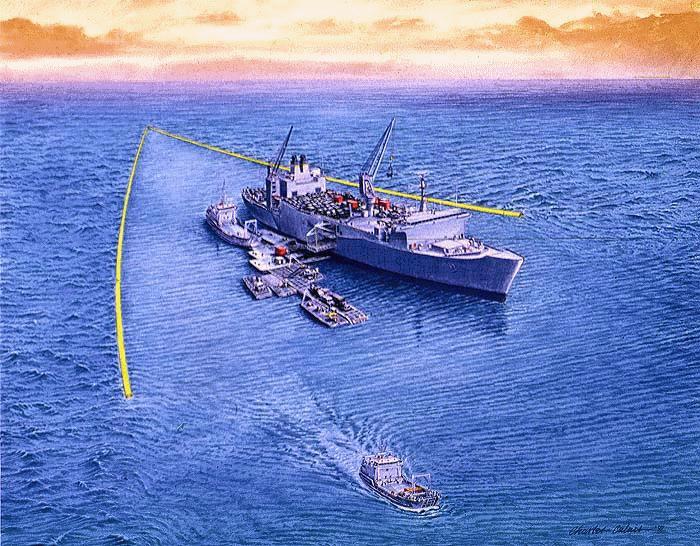

Following the XM 2000 was the XM 2001. The XM

2001 was tested at at full scale, the diameter of the hull was 28 feet and the

sections were 200 feet long (figure 9). Figure 10 is a picture of the XM

2001 during fabrication. During transportation the sections were

very compact, only requiring one flat bed semi trailer. The Kevlar webbing

around the hull was increased and a new method of RIB deployment was tested; a

model is shown in figure 11. The new deployment mechanisms resembles

an accordion when the RIB is stored. The new method of deployment,

shown in figure 12, was very successful, but recovery was a little more

difficult. The XM 2001 was also filled with sea water. The

improved pressure release valves, located on the top of the hull also performed

very well.

Figure 9

Figure 10

Figure 11

Figure 12

The testing of the RIBs has returned excellent results and future testing

should be continued. According to Dr. Jimmy

Fowler, "every RIB we tested in the field has reduced the waves in the Sea

State 3 by 50 percent or more; the RIB-XM 2000 actually reduced some waves

by about 70 percent.1 The optimal design has almost been found, the

only design change left is to optimize the joint connecting the two arms of the

V-shape.1 The transportability and hull strength are two other

design characteristics that need to be examined.1

The rapidly installed breakwater systems may not

only find a place in the military, but may also be commercialized. The

RIBs could be used as temporary breakwaters making the installation of a more

permanent breakwaters easier. They could also be used in rescue operations

for aircraft crashes or vessel recovery operations. 1 1. U.S.

Army Corp of Engineers. Engineer Update. March 2001, vol. 25, no. 3.

retrieved from

http://www.hq.usace.army.mil/cepa/pubs/mar01/story9.htm

2.

http://chl.wes.army.mil/research/projects/ribs/

3.

Melby et al. A Nearshore Rapidly-Installed Breakwater for

Military Force Projection and Sustainment Operations.

4. Dr. Larry Fowler's presentation, Rapidly Installed

Breakwater Update, at the R&D Symposium: Joint Logistics Over-the -Shore and

Logistics From the Sea. The

presentation was given on January 30, 2002.

5. Dr. Larry Fowler's presentation, RIB/ATD Update, at

the R&D Symposium: Joint Logistics Over-the -Shore and Logistics From the Sea.

The presentation was given on January 31, 2001.

6. Dr. Larry Fowler's presentation, RIBs Update/ATD

Update, at the R&D Symposium: Joint Logistics Over-the -Shore and Logistics From

the Sea. The presentation was given on February 2, 2000.

University

of Wisconsin-Madison

Department

of Civil and Environmental Engineering

CEE

514: Coastal Engineering

Professor

Chin Wu

Fall

Semester of 2003